| Lean Manufacturing is a systematic way to deliver

the :

- highest quality,

- lowest cost products with the

- shortest lead-times through the

- relentless elimination of waste.

Lean manufacturing is simply a continuously

progressive way of producing what the customer

wants, when they want it, at a price they are

prepared to pay and using least resources

HISTORY OF LEAN

- Lean manufacturing was developed by the Japanese automotive

Industry, principally Toyota, following the challenge to re-build the

Japanese economy after World War-II.

- The development of Lean was little known or understood outside

Japan until the1970’s. Britain gained early experience of Lean

manufacturing from the establishments of Toyota, Nissan and

Honda plants in UK.

- Nevertheless, until the 1990s it was really only the automotive

industry that had adopted Lean manufacturing. Since then it has

spread into aerospace and general manufacturing, consumer

electronics, healthcare, construction and, more recently, to food

manufacturing and meat processing.

LEAN Principles

- Specify the value desired by the customer;

- Identify the value stream for each product providing that

value and challenge all of the wasted steps (generally nine out

of ten) currently necessary to provide it;

- Make the product flow continuously through the remaining

vale-added steps;

- Introduce pull between all steps where continuous flow is

possible; and

- Mange toward perfection so that number of steps and the

amount of time and information needed to serve the

customer continually falls.

World Class Manufacturing and Measurements that drive Customer Satisfaction

World Class Performance Goals |

Lean Manufacturing Technique Used to Achieve |

Zero-Lost Time Accidents |

· 5 S

· Visual Communication |

Zero-Unplanned Downtime

|

· 5 S

· Total Productive Maintenance(TPM) |

Zero-Scrap /Rework

|

· 5 S

· Total Productive Maintenance (TPM)

· Manufacturing Cells / One Piece Flow

· Setup Reduction

· 5 S |

Zero-Setup Time

|

· Setup Reduction |

Zero-Inventory

|

· Total Productive Maintenance (TPM)

· Manufacturing Cells / One Piece Flow

· Setup Reduction

· Kanbans |

100% Participation

|

· Leadership & Empowerment

· 5 S & Kaizen

· Total Productive Maintenance (TPM)

· Manufacturing Cells / One Piece Flow

· Setup Reduction

· Kanbans |

Types of Wastes

The elimination of waste is the goal of Lean, and Toyota

defined three broad types of wastes: muda, muri and mura

(3Ms).

- Muri focuses on the preparation and planning of the

process, or what work can be avoided proactively by design.

- Mura focuses on how the work design is implemented and

the elimination of fluctuation at the scheduling or

operations level, such as quality and volume.

- Muda is traditional general Japanese term for activity that is

wasteful and doesn't add value or is unproductive

The Original Seven Mudas

- Transportation

- Inventory

- Motion

- Waiting

- Overproduction

- Over Processing

- Defects

Later an eighth waste described as manufacturing goods or services that do not meet customer demand or specifications.

Lean Manufacturing Tools & Techniques

- 5S System

- Visual Control

- Just in Time (JIT)

- Standard Operating Procedures (SOPs)

- Cellular Manufacturing Technology

- Value Stream Mapping

- Poke Yoke or Mistake Proofing

- Single Minutes Exchange of Dies

- Kaizen

- Kanban

- Machine Capability Studies

- Statistical Process Control (SPC)

- Total Productive Maintenance (TPM)

- Six Sigma

Benefits of Lean Manufacturing Scheme

- Reduction in waste;

- Improvement in productivity and quality;

- Introduction of innovative practices for improving overall competitiveness;

- Induce good management practices (GMP);

- Increase in manufacturing output

- Reduction in customer complaints

- Better and improved adherence to delivery schedule

- Reduction in quality rejection at every stage of production process

- Lesser inventory requirements at every stage of production

- Optimum utilization of resources in terms of space, manpower, material,

- equipment utilization and energy consumption

- Orderly work place

- Imbibe a culture of continuous improvement

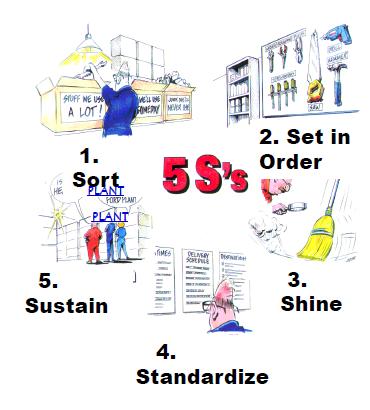

5 S

|

The 5 S concepts consistently produce an organized workplace, resulting in

- An increase in quality

- An increase in productivity

- A cleaner and safer workplace

- A reduction in required floor space.

|

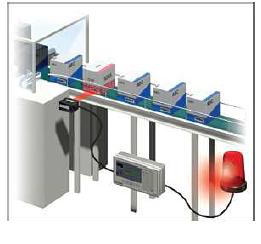

VISUAL Control

Visual systems are a form of communication and can be used to direct flow and identify problems/needs/status with minimal interaction from a person. Simple signals that provide an immediate

understanding of a situation or condition such as charts, light signals, Lane marking on floor, Safety instructions, Warning signs etc |

|

JUST IN TIME (JIT)

JIT manufacturing is a philosophy of manufacturing based on

planned elimination of waste & continuous improvement of

pr oductivity. It aims at producing the right product in right oductivity. It aims at producing the right product in right

quantity at the right time. This almost results in zero

inventory and shortest possible cycle time.

The application of JIT in Lean

Manufacturing leads to:

•Reduction in inventory by more than 50%

•Reduction in lead times by more than 50%

•Reduction in rework

•Reduction in space by more than 40%

Standard Operating Procedures (SOPs)

An SOP is a written document / instruction detailing all steps

and activities of a process or procedure. All quality impacting

processes and procedures should be laid out in Standard

Operating Procedures (SOPs). These SOPs should be the basis

for the routine training program of each employee.

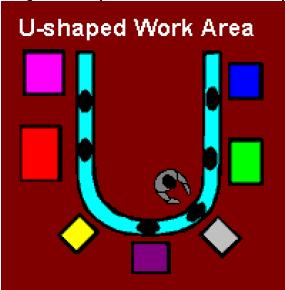

Cellular Manufacturing Technology

A manufacturing cell or work cell comprises a group of

equipment, usually laid out in the shape of a “U” that is

dedicated to the complete production of a family of similar

parts. These manufacturing cells produce parts, one at a time,

by linking together a sequence of machine or assembly

operations in a smooth production flow known as One Piece

Flow Production. usually laid out in the shape of a “U” that is

dedicated to the complete production of a family of similar

parts. These manufacturing cells produce parts, one at a time,

by linking together a sequence of machine or assembly

operations in a smooth production flow known as One Piece

Flow Production.

Value stream mapping

Value stream mapping is a Lean technique used to analyze

the flow of materials and information currently required to

bring a product or service to a consumer. Value stream

mapping is commonly used in Lean environments to identify

opportunities for improvement in lead time.

Although value stream mapping is often associated with

manufacturing, it is also used in logistics, supply chain,

service related industries, product development etc.

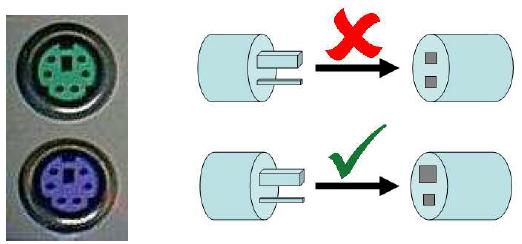

Poke Yoke Mistake Proofing

It is a Japanese technique used to prevent errors occurring at

their source of origin, and it finally leads to a 'Zero Defect'

situation. The idea behind Poke Yoke is to free a person’s

mind from maintaining repetitive vigil which may be

practically not feasible. It is extremely cost-effective lean

manufacturing tool, using very simple devices to prevent the

production of defective products.

Single Minute Exchange of Die (SMED)or Quick ChangeOver

Single Minute Exchange of Die (SMED) is one of the many lean

production methods for reducing waste in a manufacturing

process. It provides a rapid and efficient way of converting a

manufacturing process from running the current product to

running the next product. This rapid changeover is key to

reducing production lot sizes and thereby improving flow .The

phrase "single minute" does not mean that all changeovers and

startups should take only one minute, but that they should take

less than 10 minutes. Primarily it enables a manufacturing

organisation to move from a "minimum batch quantity"

approach to a "batch of one" approach. lot sizes and thereby improving flow .The

phrase "single minute" does not mean that all changeovers and

startups should take only one minute, but that they should take

less than 10 minutes. Primarily it enables a manufacturing

organisation to move from a "minimum batch quantity"

approach to a "batch of one" approach.

Total Productive Maintenance (TPM)

TPM focuses on the objective of zero breakdowns. Significant

emphasis is given on first line preventive maintenance by

operators, which is then supported by a regime of preventive

maintenance provided by specialists

The benefits of TPM implementation are:

- Improve productivity

- Reduce breakdown leading to Zero Breakdown concept

- Leads to multi-skilling of workers

- Better safety

- Improve quality of products.

Kaizen

Kaizen is a Japanese word meaning "improvement," that calls for

never-ending efforts to improve, inviting each and every one in

the organization to take part. Doing “little things “better

everyday defines Kaizen- slow, gradual but constant

improvements-continuous improvement in any area that will

eliminate waste and improve customer satisfaction.

The target of Kaizen is cost reduction through the elimination of

waste at all levels in the manufacturing process.

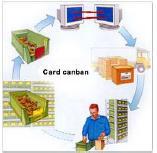

Kanban

Kanban stands for Kan- card, Ban- signal. The essence of the

Kanban concept is that a supplier or the warehouse should only

deliver components to the production line as and when they are

needed, so that there is no storage in the production area.

Within this system, workstations located along production lines

only produce/deliver desired components when they receive a

card and an empty container, indicating that more parts will be

needed in production

Kanbans are:

- Communication device; from the point of use to the previous

operation (customer to supplier)

- Purchase orders for suppliers

- Work order for manufacturing

- Visual communication tools

- Paperwork eliminators

Quality Functions Deployment (QFD)

QFD helps transform customer needs (the voice of the customer)

into engineering characteristics a product or service, prioritizing

each product or service characteristic while simultaneously

setting development targets for product or service.

QFD encourages organization to focus on the process itself

rather than just on the product or service By establishing

correlation between what is wanted and how it is to be delivered

, the vital aspects become more visible, aiding decision- making.

Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) is methodology for

analyzing potential reliability problems early in the development

cycle where it is easier to take actions to overcome these issues,

thereby enhancing reliability through design. FMEA is used to

identify potential failure modes, determine their effect on the

operation of the product, and identify actions to mitigate the

failures. A crucial step is anticipating what might go wrong with

a product.

The types of FMEA are:

- System - focuses on global system functions

- Design - focuses on components and subsystems

- Process - focuses on manufacturing and assembly processes

- Service - focuses on service functions

- Software - focuses on software functions

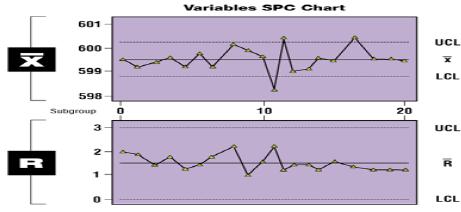

Statistical Process Contorl (SPC)

SPC involves establishing the limits of statistical variability for a

system output parameter in steady state conditions. Limits for

the variability of the process are calculated and control limits

set, which mean that when not under steady state conditions

and the output variable either falls below the lower control limit,

or climbs a bove the upper control limit the process, In lean

manufacturing environments this is considered to be an

extremely effective quality tool, requiring only periodic bove the upper control limit the process, In lean

manufacturing environments this is considered to be an

extremely effective quality tool, requiring only periodic

measurement of system output variables, and thus low

administrative costs.

Machine capability studies

Machine capability studies are carried out using SPC techniques

to establish the statistical variability of an output parameter

from a machine in steady state conditions. If the engineering

tolerances required by products produced by the machine are

within its steady state limits of variability, the machine is said to

be "capable" of the tolerances.

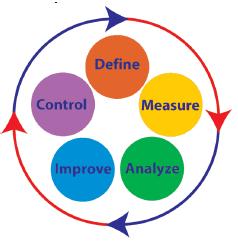

Six Sigma

Six Sigma is defined as "a program aimed at the near elimination

of defects from every product, process and transaction". O thers

defined it as a strategic initiative to boost profitability, increase thers

defined it as a strategic initiative to boost profitability, increase

market share and improve customer satisfaction through the use

of statistical tools that can lead to breakthrough quantum gains

in quality.

If deployed correctly, Six Sigma has the ability to generate a host

of benefits to business companies, e.g., improving process

speed, raising quality levels, reducing costs, increasing

revenues, and deepening customer relationships,

Benefits of Lean Manufacturing

- Reduction in waste;

- Improvement in productivity and quality;

- Introduction of innovative practices for improving overall

competitiveness;

- Induce good management practices (GMP);

- Increase in manufacturing output

- Reduction in customer complaints

- Better and improved adherence to delivery schedule

- Reduction in quality rejection at every stage of production process

- Lesser inventory requirements at every stage of production

- Optimum utilization of resources in terms of space, manpower,

material, equipment utilization and energy consumption

- Orderly work place

- Imbibe a culture of continuous improvement

|

ISO Consultants in Kolkata

ISO Consultants in Kolkata  Quality Foundation

Quality Foundation